JIAOZUO ZHONGWEI SPECIAL PRODUCTS PHARMACEUTICAL CO.,LTD

| Availability: | |

|---|---|

Polyvinylpyrrolidone (PVP) is available as a white to off-white or light yellow free-flowing powder, or as a clear, viscous liquid.

It is odorless or has a faint characteristic odor and is known for being non-toxic, non-irritating, and hygroscopic.

PVP is readily soluble in water, alcohols, amines, halogenated hydrocarbons, and many other organic solvents, while remaining insoluble in acetone and ether.

This versatile polymer offers excellent solubility, film-forming ability, biocompatibility, chemical and thermal stability, physiological inertness, and strong adhesion properties.

It also exhibits remarkable complexation capacity with a wide range of organic and inorganic substances and maintains good stability under acidic, saline, and high-temperature conditions.

Thanks to this unique combination of properties, PVP has found widespread application across diverse industries, including pharmaceuticals, cosmetics, food processing, adhesives, coatings, and more.

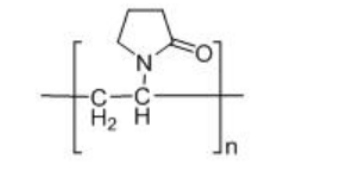

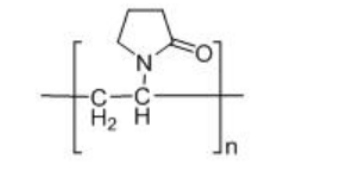

Structure formula:

Appearance: White or yellowish-white powder

Product characteristics: This product has excellent dispersion performance for nanomaterials and good stability, which is suitable for the dispersion of carbon nanotubes in NMP and the preparation of nano-silver materials by chemical reduction method.

Application:

K25, K30:suspensant, dispersers and emulsifier, paint and coating, film, glass fiber, ink, detergent,textile and dye printing.

K90: adhesive.

PVP K15 | PVP K17 | PVP K25 | PVP K30 | PVP K60 | PVP K90 | PVP K120 | |

pH | 3.0-7.0 | 3.0-7.0 | 3.0-7.0 | 3.0-7.0 | 3.0-7.0 | 3.0-7.0 | 3.0-7.0 |

K-value | 13.0-18 | 15.30-18.36 | 24.0-27.0 | 27.0-32.4 | 54.0-64.8 | 81.0-97.2 | 108.0-130.0 |

NVP (ppm) | ≤2000 | ≤2000 | ≤2000 | ≤2000 | ≤2000 | ≤2000 | ≤2000 |

Water (%) | ≤5.0 | ≤5.0 | ≤5.0 | ≤5.0 | ≤5.0 | ≤5.0 | ≤5.0 |

Sulfated ash (%) | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 |

Nitrogen (%) | 11.5-12.8 | 11.5-12.8 | 11.5-12.8 | 11.5-12.8 | 11.5-12.8 | 11.5-12.8 | 11.5-12.8 |

Excellent binding and dispersing capacity

High compatibility with organic/inorganic substances

Strong adhesion and film-forming properties

Physiologically inert and non-toxic

Stable under acidic, salty, and high-temperature conditions

Industrial-grade polyvinylpyrrolidone (PVP) serves as a highly effective dispersant, binder, and thickening agent across a variety of industrial sectors.

It plays a vital role in household care products, detergents, textiles, papermaking, petroleum recovery,

and is widely used in adhesives such as glue sticks, as well as in coatings, paints, pigments, dyes, inkjet printing, and ceramic processing.

Its excellent solubility and stabilizing properties also make it suitable for nanomaterials, sensitive materials, and various electronic applications.

In addition, industrial-grade PVP is extensively applied in high-tech fields such as membrane separation,

UV-curable resins, photocurable coatings, optical fibers, laser discs, and drag-reducing materials, thanks to its chemical stability and multifunctionality.

25kg fiber drums or customized packaging on request

Store in a dry, ventilated area away from heat and moisture. Keep the container tightly closed.

Povidone (PVP K-series) is widely used as a dispersant, binder, thickener, and stabilizer in various industries including household care, textiles, paper manufacturing, adhesives (such as glue sticks), coatings, paints, dyes, ceramics, nanomaterials, and inkjet printing. It also finds applications in UV-cured resins, separation membranes, fiber optics, and advanced materials.

Industrial PVP is typically classified based on its molecular weight: K12, K15, K17, K25, K30, and K90. The K-value affects its viscosity and film-forming ability, making different grades suitable for different applications.

PVP offers excellent dispersibility for pigments and dyes, enhances viscosity control, and improves film adhesion. It also provides stability against precipitation and enhances gloss in printing inks and coating formulations.

Yes. PVP is used in high-end applications such as semiconductors, laser optical discs, optical coatings, and anti-fouling or drag-reducing materials due to its excellent solubility, compatibility, and film-forming properties.

Industrial-grade PVP is optimized for performance in technical applications and may not meet the purity and safety standards required for pharmaceutical or personal care use. Pharmaceutical-grade PVP adheres to strict regulations like USP, EP, or JP standards.

Polyvinylpyrrolidone (PVP) is available as a white to off-white or light yellow free-flowing powder, or as a clear, viscous liquid.

It is odorless or has a faint characteristic odor and is known for being non-toxic, non-irritating, and hygroscopic.

PVP is readily soluble in water, alcohols, amines, halogenated hydrocarbons, and many other organic solvents, while remaining insoluble in acetone and ether.

This versatile polymer offers excellent solubility, film-forming ability, biocompatibility, chemical and thermal stability, physiological inertness, and strong adhesion properties.

It also exhibits remarkable complexation capacity with a wide range of organic and inorganic substances and maintains good stability under acidic, saline, and high-temperature conditions.

Thanks to this unique combination of properties, PVP has found widespread application across diverse industries, including pharmaceuticals, cosmetics, food processing, adhesives, coatings, and more.

Structure formula:

Appearance: White or yellowish-white powder

Product characteristics: This product has excellent dispersion performance for nanomaterials and good stability, which is suitable for the dispersion of carbon nanotubes in NMP and the preparation of nano-silver materials by chemical reduction method.

Application:

K25, K30:suspensant, dispersers and emulsifier, paint and coating, film, glass fiber, ink, detergent,textile and dye printing.

K90: adhesive.

PVP K15 | PVP K17 | PVP K25 | PVP K30 | PVP K60 | PVP K90 | PVP K120 | |

pH | 3.0-7.0 | 3.0-7.0 | 3.0-7.0 | 3.0-7.0 | 3.0-7.0 | 3.0-7.0 | 3.0-7.0 |

K-value | 13.0-18 | 15.30-18.36 | 24.0-27.0 | 27.0-32.4 | 54.0-64.8 | 81.0-97.2 | 108.0-130.0 |

NVP (ppm) | ≤2000 | ≤2000 | ≤2000 | ≤2000 | ≤2000 | ≤2000 | ≤2000 |

Water (%) | ≤5.0 | ≤5.0 | ≤5.0 | ≤5.0 | ≤5.0 | ≤5.0 | ≤5.0 |

Sulfated ash (%) | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 |

Nitrogen (%) | 11.5-12.8 | 11.5-12.8 | 11.5-12.8 | 11.5-12.8 | 11.5-12.8 | 11.5-12.8 | 11.5-12.8 |

Excellent binding and dispersing capacity

High compatibility with organic/inorganic substances

Strong adhesion and film-forming properties

Physiologically inert and non-toxic

Stable under acidic, salty, and high-temperature conditions

Industrial-grade polyvinylpyrrolidone (PVP) serves as a highly effective dispersant, binder, and thickening agent across a variety of industrial sectors.

It plays a vital role in household care products, detergents, textiles, papermaking, petroleum recovery,

and is widely used in adhesives such as glue sticks, as well as in coatings, paints, pigments, dyes, inkjet printing, and ceramic processing.

Its excellent solubility and stabilizing properties also make it suitable for nanomaterials, sensitive materials, and various electronic applications.

In addition, industrial-grade PVP is extensively applied in high-tech fields such as membrane separation,

UV-curable resins, photocurable coatings, optical fibers, laser discs, and drag-reducing materials, thanks to its chemical stability and multifunctionality.

25kg fiber drums or customized packaging on request

Store in a dry, ventilated area away from heat and moisture. Keep the container tightly closed.

Povidone (PVP K-series) is widely used as a dispersant, binder, thickener, and stabilizer in various industries including household care, textiles, paper manufacturing, adhesives (such as glue sticks), coatings, paints, dyes, ceramics, nanomaterials, and inkjet printing. It also finds applications in UV-cured resins, separation membranes, fiber optics, and advanced materials.

Industrial PVP is typically classified based on its molecular weight: K12, K15, K17, K25, K30, and K90. The K-value affects its viscosity and film-forming ability, making different grades suitable for different applications.

PVP offers excellent dispersibility for pigments and dyes, enhances viscosity control, and improves film adhesion. It also provides stability against precipitation and enhances gloss in printing inks and coating formulations.

Yes. PVP is used in high-end applications such as semiconductors, laser optical discs, optical coatings, and anti-fouling or drag-reducing materials due to its excellent solubility, compatibility, and film-forming properties.

Industrial-grade PVP is optimized for performance in technical applications and may not meet the purity and safety standards required for pharmaceutical or personal care use. Pharmaceutical-grade PVP adheres to strict regulations like USP, EP, or JP standards.